How do we regulate it?

Energy consumption and production activities are responsible for two-thirds of global greenhouse gas (GHG) emissions (WEF, 2018: 6).

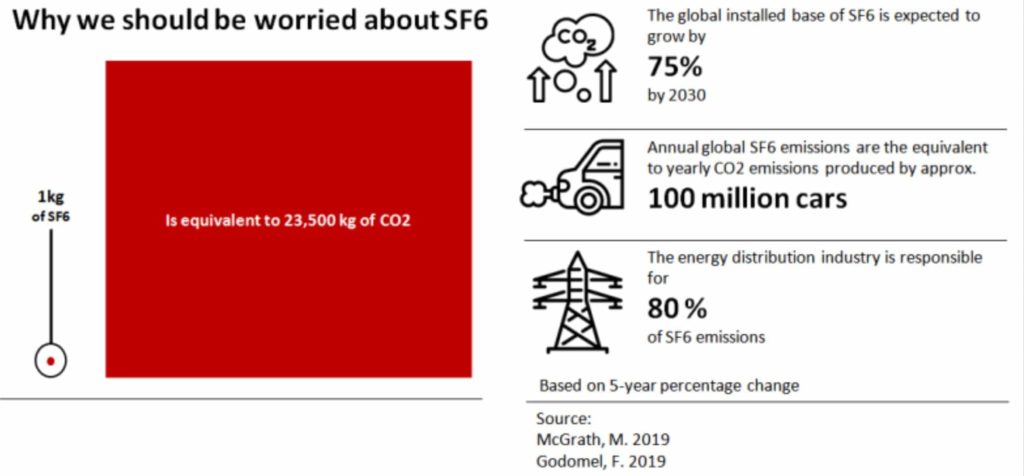

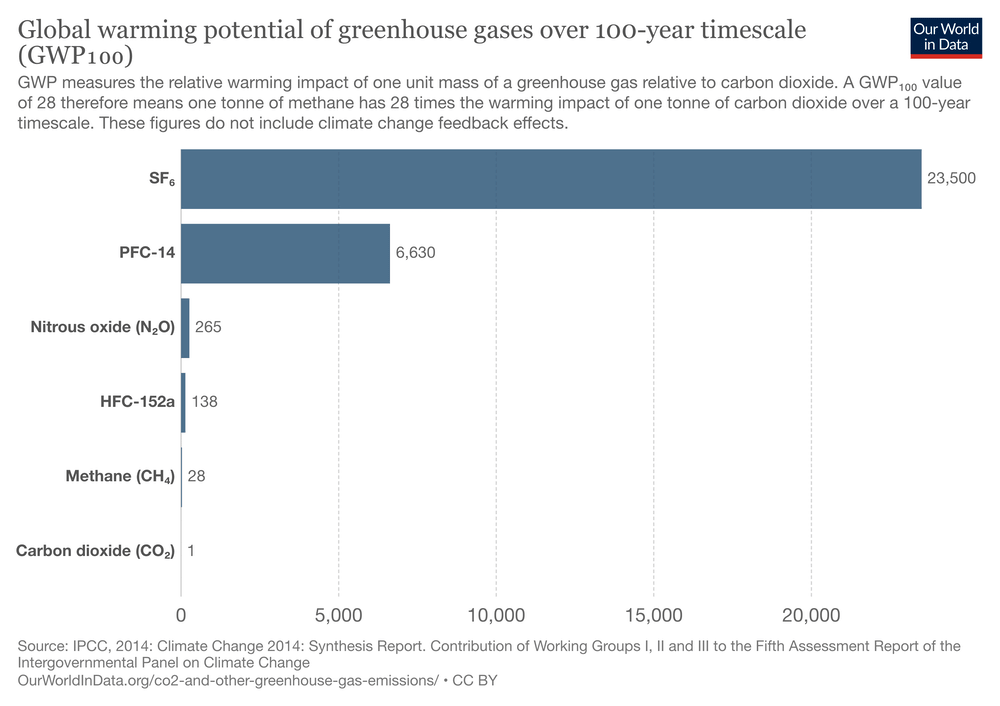

80% of all SF6 produced is used as an insulating medium for GIS (Powell, 2002: 6), and its global annual emissions are 8,100 tonnes (Dunse et al, 2015: 20); the equivalent to the yearly CO2 emissions produced by approximately 100 million new cars, which is more than annual worldwide care sales. Moreover, it has an atmospheric lifetime of 3,200 years and its installed base is expected to grow by 75% by 2030 (McGrath, M. 2019). California and the EU have now put it on the agenda. The EU will review the use of SF6 next year and will examine whether alternatives are available. However, even the most optimistic experts don’t think that any ban is likely to be put in place before 2025.

SF6 in the gas-insulated switchgear industry

SF6 has two uses: as an interruption agent and an insulator.

“Unlike a light switch that breaks a simple electrical circuit, doing the same in a higher-rated application is more challenging and additional protection is needed. Typically, a mechanical circuit breaker is used inside a pocket of SF6 gas that to extinguish the electric arc. At present, it is the most compact and cheapest method of safely stopping the flow of electricity,” explains SINTEF researcher Atle Pedersen.

BBC: Electrical industry’s ‘dirty secret’ boosts warming

“There are no secrets surrounding the use of SF6 in Norway’s energy industry. In fact, it’s quite the opposite,” SINTEF researcher Maren Istad. She is secretary of the SF6 User Group, an association of 47 public and private companies all openly sharing their experiences with SF6. The User Group for SF6 systems in Norway was founded in 1991.

Ironically then;

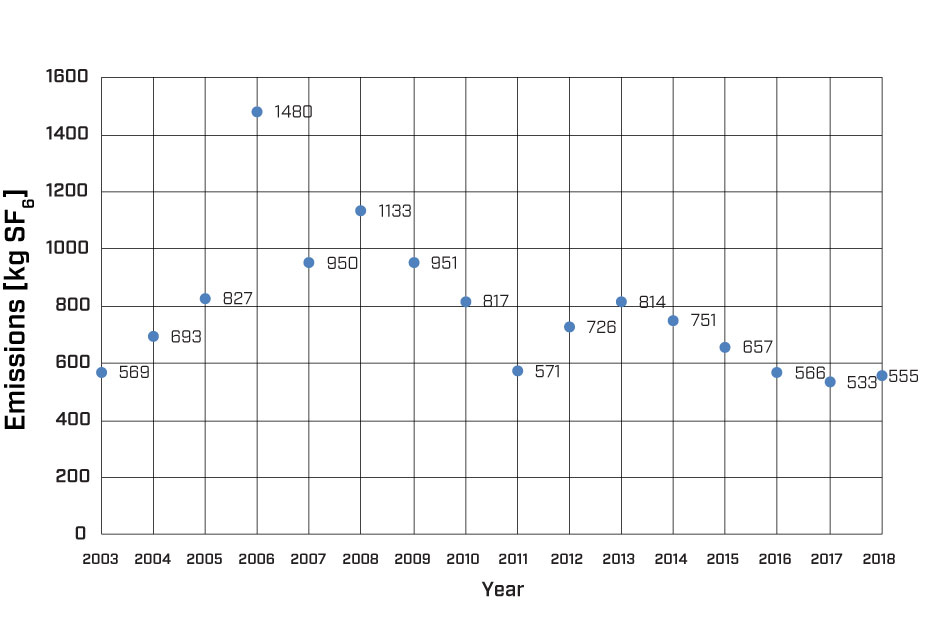

At the User Meeting 2019, it was decided to change the name to “User Group for gas-insulated switchgear”. In 2018 93% of leakages were caused by leakages during ordinary operations, while 7% were caused in connection with component failure or breakdowns.

SINTEF researcher Atle Pedersen.

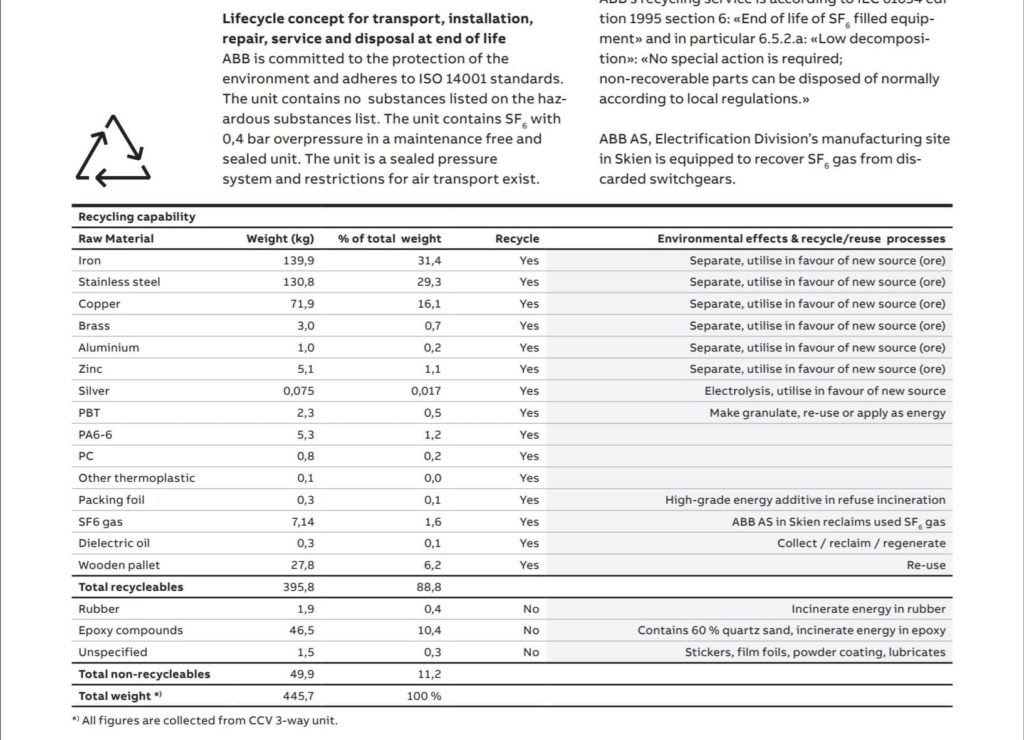

Page 76 out of 78 in this catalogue for ABB’s Super-slim switchgear for the wind segment states a different amount; more than 7 kilogram SF6 gas.

ABB SafePlus 36 Gas-insulated compact switchgear for ANSI markets page 76 of 78

The annual report for 2018 shows that emissions are at the same level as for the two previous years, with a small increase compared with 2017. The total amount of SF6 gas in use in User Group member substations during 2018 is 299,610 kg – an increase of almost 12,500 kg compared with 2017. There is also 16,941 kg of gas held in storage.

In 16 years that means 12,593 tonn of the worlds most potent green house gas is reported leaked, only in Norway. Each kilogram with the global warming potential (GWP) of the equvivalent of 23.500 CO2 units, making the total almost 300 million kilogram CO2 (295 935 500).

Across the entire UK network of power lines and substations, there are around one million kilograms of SF6 installed. A study from the University of Cardiff found that across all transmission and distribution networks, the amount used was increasing by 30-40 tonnes per year.

On the coast of Trondheim in Trøndelag, Fosen Vind is establishing Europe’s largest wind power project on land, six large wind industry areas with a total of 1057 MW.

Photo: Storheia with 80 Turbines and 288 MW.

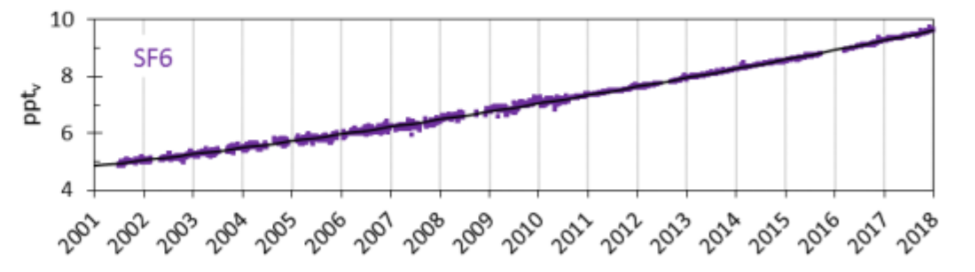

In 17 years the concentration of SF6 in the atmosphere is almost doubled.

In figure (4) can one can see how the concentration of SF6 has almost doubled since the first measurement was made in 2001. This, together with a steady increase in gas in the power sector’s construction stock, may give rise to to concern, especially since the gas has a long life in the atmosphere. It means emissions will accumulates in the atmosphere without breaking down.

Norway is a world leader in renewable energy, historically enjoying almost 100% electrification with most of the electricity in the country produced by hydroelectric power that is consistently reliable. Norway is one of the leading countries in the electrification of its transport sector, with the largest fleet of electric vehicles per capita in the world (see plug-in electric vehicles in Norway and electric car use by country). Buses and even local ferries are now also starting to run on electricity.

Those hydro power plants now typically are old and could be renewed if only governmental tax incentives did not prefer wind turbine projects which typical last 15-25 years over hydro power plants with an investment frame of 70 – 100 years.

The first wind power turbine in Norway was built in 1986 in Frøya Municipallicy in Trøndelag County. In the period 1999 – 2013, 2.1 TWh of wind power was developed in Norway, particularly along the west coast. There has been an extensive effort by the Norwegian Water Resources and Energy Directorate to develop the “National Framework for Wind Power,” published April 1. 2019.

The markets for renewable energy do not create themselves. It requires strong political commitment and facilitation, and that we really dare. In the period 2001 – 2013, the wind power industry invested NOK 7.5 billion, and the State through Enova, NOK 2.6 billion, in a technology and a market that we must not let go of now. Wind power is a climate-friendly, renewable and inexhaustible source of energy where Norway has particularly good conditions for becoming a leader.

Nils Kristian Nakstad, CEO ENOVA

From January 1. 2021 Norwegian householders will no longer get subsidies from ENOVA to put sunroofs on their houses even though sun energy is now the cheapest energy to produce and the prices are still heading down.

23 Comments

Pingback: Bisphenol A in wind turbines damages human fertility - Bergensia

Pingback: Goal 7: Affordable and Clean Energy - Bergensia

Pingback: No giant wind farm off the Færder coast! - Bergensia

Pingback: Vote green for nature; we do not need more energy - Bergensia

Pingback: pilates los angeles

Pingback: ks quik

Pingback: hell on wheels

Pingback: jarisakti

Pingback: keluaran togel online

Pingback: ชอบหีสวย.com

Pingback: sex tre em

Pingback: swan168

Pingback: car detailing

Pingback: ผ้า

Pingback: pg333

Pingback: รับซื้อแบรนด์เนม

Pingback: ราคาบอลไหล

Pingback: Telegram中文

Pingback: Vegas casino

Pingback: lost mary vapes online

Pingback: ทัวร์แคนาดา

Pingback: Dark168 คาสิโน เว็บตรง

Pingback: Impact des Eoliennes en Environnement et Santé Publique : – Enviro Veritas